Nintendo is but one company with mixed product launches: runaway hits or expensive knickknacks. If only there was a more structured approach to product development! This post summarizes my notes on the matter.

The tools available to reduce waste (Lean) and to analyze the process based on data (Six Sigma) connect to existing products. How about new products? How does one design them to be efficient in production and effective in capturing the market demand?

We luckily have a few tools both to identify a project and design a product. SIPOC is a good starting point: SIPOC is a tool for process mapping binding together all the main dimensions of a process. It helps to see the business as a cross-functional process connecting supplier and customer. The goal of this tool is to highlight what creates value and who is involved: who uses this process? The SIPOC has a magic symmetry to it, that shows the flow of value while centering on the process itself. I like it.

| Suppliers | Inputs | Process | Output | Customer |

It is important to set project boundaries to determine who is involved in the process. It assigns inputs to suppliers and customers: the entity waiter can be both a supplier of inputs (e.g. table request to the kitchen), and customer in outputs (e.g. collects the cash payment at the table).

The madness of some stakeholders analyses

Sometimes stakeholder analysis is completely superfluous in its desire to bring structure. An example is mapping the level of commitment of departments and people involved in the process. Instead of saying “Bob doesn’t like doing this” you create a scoreboard:

| Level of commitment | Sales | Warehouse | Delivery guy |

| Supporting | Desired level | ||

| Helping | Desired level | ||

| Compliant | Desired level | ||

| Hesitant | Current level | ||

| Indifferent | Current level | Current level | |

| Uncooperative | |||

| Opposed | |||

| Hostile |

Does the customer want it?

The goal is simple: to design, manufacture, and support products and processes to deliver what the customer wants. The need for a new product may come from strategy needs: e.g. it is expected from Apple to launch a new handset every year, both to sustain the value perception and to be seen as an innovative enterprise. When development costs are reasonable, the need may come from sales as it is easier for organizations to push new products instead of addressing the broader sales strategy: Nintendo is notorious for pushing products to the customer base attracted by its once-per-decade runaway success.

Regardless of the initial need for new products, DFSS deploys methods to understand what needs to be included in the new product (or new iteration) and how to design the process to meet customer needs. Examples are:

- the Voice-Of-the-Customer captures needs, wants, and expectations

- to know delighters (features to add to increase satisfaction), focus groups, observational studies can tell a lot. In uncertain, improve the ease-of-use and you won’t be wrong;

- to know satisfiers you can use market research (survey, interviews);

- to know dissatisfiers it is important to create a space for sharing bad news. This can be done with one-on-one interviews to spot missing functional requirements: account managers are usually a good source of information since they regularly talk to our customers.

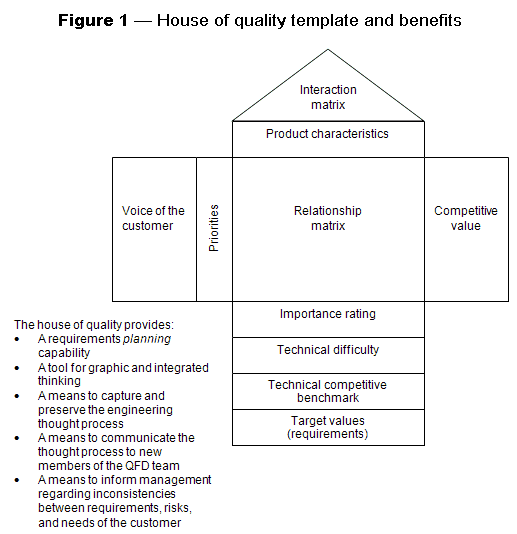

- the Quality Function Deployment allows to bring together customer expectations, and technical struggles checking the strongest interactions between elements

- FMEA assesses how things can break (failure mode) and its consequences (effects analysis). It evaluates risk by analyzing historic data, especially when it is unclear what needs to be done: it gives each failure mode a risk priority number. This comes from experts rating severity, occurrence, and detection of failures on a 1-5 scale

- benchmarking shows what similar solutions are offering: it can be process, performance, project (control), and strategic (about competitors)

The core idea is that DFSS is proactive and focuses on the market (“do customers actually want my new product?”). Six Sigma focuses more on improving an existing process, whereas DFSS designs an effective process from the ground up. The idea is to reduce time to market, warranty cost and lifecycle cost.

What is critical to customer satisfaction?

There are different ways to understand customers. Managers love measuring it with numbers to make it look like sentiments are quantitative: the net promoter, the customer satisfaction, or the customer ease score. I personally admire other approaches from the a-rational consumer viewpoint popularized by Rory Sutherland’s Alchemy: the surprising power of ideas that don’t make sense. However, let’s be real: we need solid measurable frameworks for the next meeting.

Customers make considerations of quality, design, cost, and process that we can understand and record. We may organize them in an affinity diagram so that the causal nexus (“but why?”) can be presented. This should develop a Critical to Satisfaction metric (CTS). CTS is a function of process characteristics and is a composite measure of critical to quality, design, and cost scores

Quality function deployment (QFD)

The House of Quality is the most telling visualization for connecting customer and product: What the customer wants is on the left, what our customers think of your competitors are to the right; The competitive assessment lies at the bottom, the technical requirements (how are we going to satisfy needs) are at the top. The roof tells the interaction between technical requirements.

More than just a plan

Of course, finding the best features to develop is just part of the whole process. We need a plan, or as they call it in LSS, a project charter with: problem statement (why do we need the project?), purpose (what are we trying to achieve?), benefits (how will it help the company?), scope (when is this project done?), and results in a single document.

Often a project plan is needed to answer questions on duration, resources needed, measurements, and communication to stakeholders. In the project documentation we will need all of the most important parts noted and crossed: goals, milestones, plans, budgets, roles, sponsors, responsibilities, deliverables, and metrics. These are the building blocks of a story board. Part of the planning involves identifying risk (e.g. through SWOT or FMEA), as well as closure eventually with an assessment (e.g. in a debriefing, after-action-report, audit): you don’t want to negotiate when the work is done.

Design for Six Sigma (DFSS)

Common methodologies include:

IDOV (identify, design, optimize, validate)

- identify new products

- design alternatives and functional requirements (“critical to quality characteristics”)

- optimize by first setting how consistent is the process in the desired output (the “process capability information”) in terms of its statistical tolerance and robustness

- Finally, we validate (test and confirm) the process.

DMADV (define, measure, analyze, design, verify)

- Define the project goal

- Measure determining customer needs and specifications

- Analyze the options

- Design a process meeting customer demand

- Verify (validate)

Design for Excellence

The idea of designing an excellent product is not new. Note that excellence is a relative term and leads to discussions in the meeting board: the perfect production is a negotiated quantity. Companies have initiatives to achieve their stated goals and you can:

- design with concurrent engineering

- design for manufacturability (or for assembly)

- design for repair

- design for the environment

- design for reliability (focusing on mean time to failure)

- design for usability

- design for scalability

- design for safety (best combined with FMEA)

- design for agility (fast to market)

- …

Concluding notes

Nobody can guarantee that a product will be a runaway success. These techniques are usually better on paper than in reality, and it is easy to get lost into detail while the whole process should focus on one main interest: the customer.

By bringing constantly the customer in the solution, these techniques avoid organizations to get lost into internal ideas. Often companies try and develop what they are comfortable with, not what the market asks for. These are not long for the business world.

I am preparing the Green Belt Six Sigma certification from Kennesaw State University. I am impressed by the production quality of the online materials and the simple, direct explanations in bite-sized servings. Highly recommended.

Most of my materials come from this excellent source.

For Quality Function Deployment, check this old publication by Donald S. Ermer & Mark K. Kniper (1998) Delighting the customer: Quality function deployment for quality service design, Total Quality Management, 9:4-5, 86-91, DOI

Leave a comment